Sunresin丨Innovative Continuous Ion Exchange Solutions for the 1,4-Butanediol Industry

1,4-Butanediol Applications

1,4-Butanediol (BDO) is an essential raw material in both organic and fine chemical industries, critical in the production of high-value derivatives like polybutylene terephthalate (PBT), polyurethane resins, spandex, γ-butyrolactone, and N-methylpyrrolidone. These derivatives find broad applications in sectors such as pharmaceuticals, cosmetics, solvents, plasticizers, curing agents, pesticides, synthetic leathers, fibers, and engineering plastics, adding significant value across diverse markets.

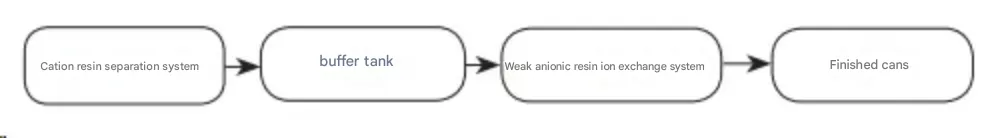

Continuous Ion Exchange Process in BDO Production

During 1,4-butanediol production, a crude solution of 1,4-butynediol forms through the catalytic reaction of acetylene and formaldehyde. This solution often contains impurities, including cations (Na+, Ca2+, Mg2+, Cu2+) and anions (SO42-, SiO32-, HCOO-, CH3COO-), which can harm subsequent hydrogenation catalysts. Effective deionization is crucial to protect catalyst longevity and ensure product quality. Sunresin's Continuous Ion Exchange (CIE) system addresses this need, featuring a two-step process with cation and anion exchange beds for high-purity outputs.

Challenges with Conventional Fixed-Bed Systems – Customer Case

For a BDO production facility with a capacity of 180,000 tons per year, conventional fixed-bed adsorption systems often present major challenges:

- 1.Low Resin Utilization: Fixed-bed systems require large resin beds to achieve the needed adsorption, leading to oversized equipment, uneven flow distribution, and resin utilization rates of only 40-50%.

- 2.Excessive Wastewater: The large volumes of chemicals needed for regeneration lead to significant wastewater production, placing a burden on wastewater treatment facilities.

- 3.Operational Instability: Fixed-bed adsorption processes lack automation, making operations susceptible to variations in manual control.

Given these limitations, transitioning to an automated, high-efficiency system with improved resin utilization and lower wastewater output is essential.

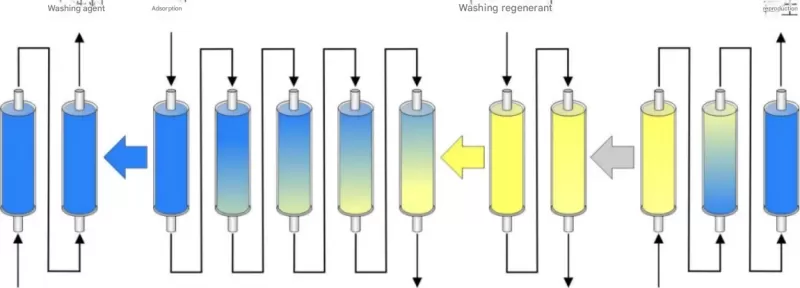

Sunresin’s Innovative CIE System

Sunresin’s CIE system divides conventional resin beds into several segments, allowing each segment to operate continuously in different stages—adsorption, washing, elution, and regeneration - within a single, integrated system. This unique design significantly boosts material stability and resin utilization while reducing both chemical usage and wastewater discharge.

Diagram: Continuous Ion Exchange Process Flow

In this BDO facility producing 180,000 tons per year, Sunresin’s CIE system reduces wastewater discharge from approximately 80-100 m³/h by up to two-thirds compared to fixed-bed systems. Regeneration wastewater can even be repurposed in coal slurry production, further lightening the load on wastewater treatment processes.

High-Performance Monojet® Uniform Particle Resins

Sunresin’s proprietary Monojet® uniform particle size resin, manufactured through advanced jetting technology, offers a uniformity coefficient of ≤1.1. This high-strength, high-crosslinking resin, combined with Sunresin’s patented Sepsolut® CIE and simulated moving bed systems, enhances production efficiency and reduces operational costs. Our custom chromatography resin solutions, designed for various separation goals, provide tailored performance to meet specific production needs.

Advantages of Sunresin’s Continuous Ion Exchange System

In BDO production facilities, Sunresin’s CIE system offers:

- 1.Continuous Operation with Strong System Compatibility: Ensures uninterrupted performance and reliable integration.

- 2.Compact, Efficient Design: Reduced equipment footprint with fewer pipes.

- 3.High Resin Utilization: Optimizes resin efficiency with stable product yield, concentration, and purity.

- 4.Reduced Consumption of Water and Chemicals: Minimizes resource use and waste generation.

- 5.Flexible Operation: Automatically adjusts flow rate and speed to match production load, ensuring process adaptability.

- 6.Eco-Friendly: Low “three-waste” emissions reduce environmental impact.

Drive Innovation in Your Operations with Sunresin

With the industry's increasing focus on efficiency, stability, and sustainability, Sunresin’s Continuous Ion Exchange system is the choice for forward-thinking producers in the 1,4-butanediol market. By enhancing operational efficiency and reducing environmental impact, Sunresin’s solution helps companies stay competitive and compliant in an evolving regulatory landscape.

Explore the Future of Production

Contact us today to learn how Sunresin’s advanced ion exchange solutions can elevate your production and sustainability goals. Sunresin – Driving Innovation in Separation and Purification Technology.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

19

2025 11

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit