INDUSTRY

With its in-depth R&D of ion exchange and adsorption resins, depending on processional supporting equipment design capabilities and project organization capabilities, Sunresin has achieved the separation and purification solutions for various industries.

PRODUCT

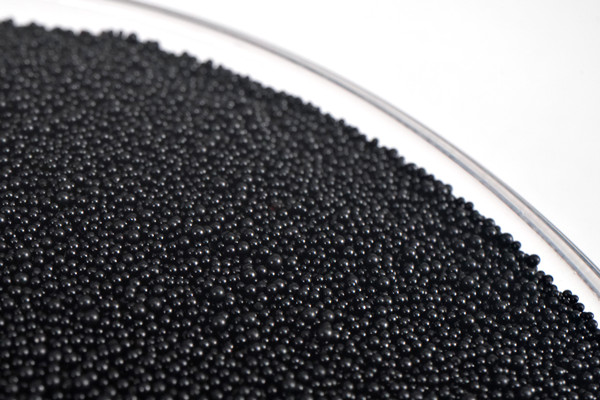

As a leading ion exchange resin manufacturer in China, Sunresin is manufacturing an extensive resin series, and

delivering the supporting equipment and EPC project of separation & purification process.

NEWS & EVENTS

[Company News]

Dec 06,

2025

Sunresin’s International Symposium on Peptide and Oligonucleotide Technologies Concludes Successfully at Its Global Headquarters in Xi’an

[Company News] Dec 03, 2025

Sunresin Advances Global Peptide and Oligonucleotide Innovation with Breakthrough Solid-Phase Synthesis Carriers

[Company News] Nov 19, 2025

Sunresin CEO Ivy Gao nominated for

[Company News] Oct 25, 2025

Sunresin Establishes Subsidiary in Sweden to Strengthen Global Life Sciences Strategy

CASE STUDY

02 26

2026

Sunresin Continuous Chromatography and Resin Solutions for the Amino Acid Industry

Sunresin has developed advanced resin materials and integrated continuous separation technologies specifically designed for large-scale amino acid production. Through continuous innovation in material science and process engineering, Sunresin provides industrially proven purification solutions covering fermentation broth treatment, mother liquor recovery, desalination and high-resolution amino acid separation.

Read More

02 09

2026

A Flexible Fluid Distribution System Enhancing Ion Exchange and Resin Regeneration Efficiency

Ion exchange and resin regeneration processes are widely applied in water treatment, hydrometallurgy, chemical processing, and resource recovery. In multi-column systems, achieving continuous operation, precise fluid routing, and high resin utilization is critical to overall system performance.

Read More

01 28

2026

A Modular Cartridge Filter Design Improving Reliability and Maintainability of Large-Scale Adsorption Columns

In large-scale adsorption systems handling high gas flow rates, internal filtration components play a critical role in protecting adsorption media and ensuring stable long-term operation.

Read More

01 19

2026

An Optimized Resin Column Design Enhancing Gas Distribution and Adsorption Efficiency in Industrial Applications

Adsorption technology is widely applied in industrial off-gas treatment and carbon capture processes due to its high selectivity, flexibility, and energy efficiency. Within these systems, the resin column serves as the core equipment that houses adsorption media and governs how process gas flows through the bed.

Read More

01 09

2026

An Integrated VOCs Treatment System Delivering High Efficiency, Compact Design, and Reliable Industrial Operation

As environmental regulations become increasingly stringent, effective control of volatile organic compounds (VOCs) has become a critical requirement for industrial operations in sectors such as chemicals, metallurgy, pharmaceuticals, and specialty manufacturing.

Read More

01 04

2026

Enhancing Gold Recovery with SepGold® Resin-Based Technology

A Mobile Sorption Module Solution Using Seplite® Gold-Selective Resins

Read More