Efficient Chromatographic Purification of Lactoferrin from Dairy Streams and Fermentation Broth

Case Study: Purification of Lactoferrin Using Seplife® Cation Exchange Chromatography

Lactoferrin is a high-value iron-binding glycoprotein widely used in nutrition, functional foods, infant formula, and other health-related applications. As demand for high-purity lactoferrin continues to grow, manufacturers are seeking purification technologies that can deliver high recovery, excellent purity, and reliable scalability across different production routes.

In practice, lactoferrin can be sourced from both dairy streams (such as milk and whey) and fermentation broth. These feedstocks differ significantly in composition and lactoferrin concentration, placing different technical demands on downstream purification. Chromatographic purification—particularly strong cation exchange chromatography—has become one of the most effective and widely adopted approaches to meet these requirements.

Chromatographic Strategy for Lactoferrin Purification

Lactoferrin carries a net positive charge under mildly acidic conditions, making it well suited for capture using strong cation exchange (SP) resins. In a typical process, lactoferrin is adsorbed onto the resin matrix and subsequently eluted using a controlled salt gradient, most commonly sodium chloride.

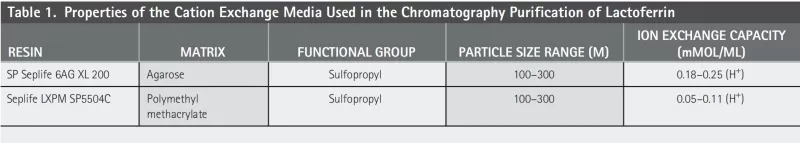

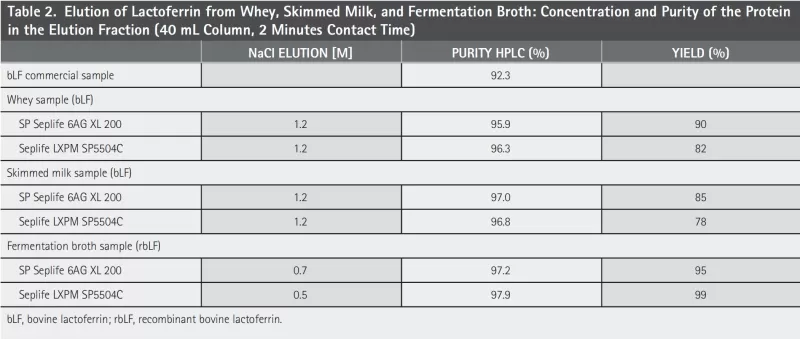

To evaluate purification performance under different feed conditions, two industrial chromatography media from Sunresin’s Seplife® product line were assessed:

- SP Seplife® 6AG XL 200, an agarose-based, highly hydrophilic strong cation exchange resin

- Seplife® LXPM SP 5504C, a rigid polymethacrylate-based strong cation exchange resin designed for high productivity

Both resins feature SP functional groups, industrial particle size distributions, and compatibility with axial and radial flow chromatography systems.

Fig. 1. Optical microscopy for the SP Seplife 6AG XL 200 and Seplife SP5504C. (A) SP Seplife 6AG XL 200 microscope picture. (B) Seplife LXPM SP 5504C microscope picture.

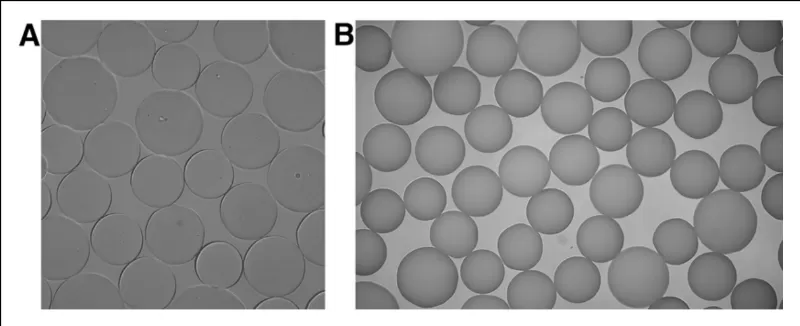

Fig. 2. Pressure flow curves of SP Seplife 6AG XL 200 (orange) and Seplife SP5504C (blue) chromatography media packed in 300 · 200 mm(d · h) column using water mobile phase.

and Seplife SP5504C (blue) chromatography media packed in 300 · 200 mm%0D%0A(d · h) column using water mobile phase._1765941682_WNo_800d433.webp)

SP Seplife 6AG XL 200 microscope picture. (B) Seplife%0D%0ALXPM SP 5504C microscope picture._1765941538_WNo_800d326.webp)

SP Seplife 6AG XL 200 microscope picture. (B) Seplife%0D%0ALXPM SP 5504C microscope picture._1765941505_WNo_800d326.webp)

Purification Performance from Dairy Sources

When purifying lactoferrin from dairy feeds such as whey and skimmed milk, matrix complexity plays a critical role. In these applications, minimizing nonspecific interactions while maintaining strong target binding is essential.

The agarose-based SP Seplife® 6AG XL 200 demonstrated excellent performance for dairy-derived lactoferrin. Its hydrophilic matrix reduced undesired interactions with milk proteins and other components, resulting in:

- Lactoferrin purity of approximately 97%

- Recovery yields of up to 90% from whey feeds

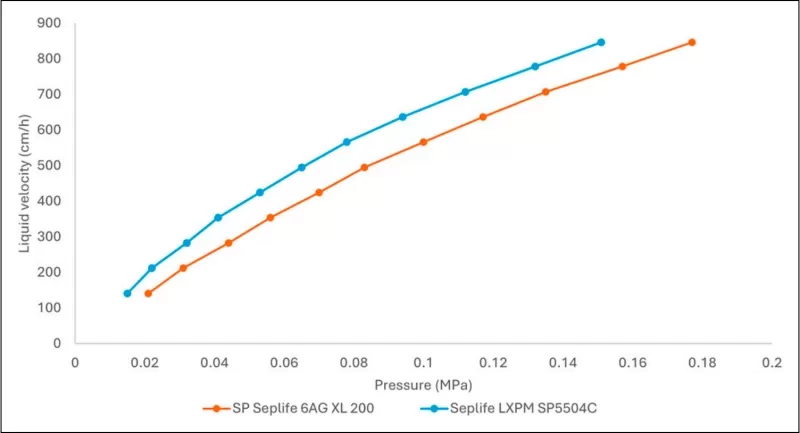

Fig. 3. Comparison of three chromatography media for lactoferrin DBC at Q10, Q50, and Q100. SP Seplife 6AG XL 200 (orange), Seplife SP5504C (blue), and SP Sepharose Big Beads (gray). Standard commercial purified bLF was used for the test in a 5 mL column (0.8 · 10 cm) with 20 mM phosphate buffer, pH 6.7 mobile phase, 2 minutes contact time for the sample application and elution using 20 mM phosphate buffer with 1 M NaCl, pH 6.7. bLF, bovine lactoferrin; DBC, dynamic binding capacity.

Operational stability was also confirmed through extended reuse testing. Over multiple cycles with sodium hydroxide cleaning-in-place (CIP), the resin maintained consistent purity and yield with minimal variation, demonstrating suitability for repeated industrial operation.

High-Productivity Purification from Fermentation Broth

For fermentation-derived lactoferrin, feed concentrations are typically much higher, shifting the purification focus toward resin capacity, productivity, and process efficiency.

In this scenario, the polymethacrylate-based Seplife® LXPM SP 5504C delivered outstanding results. The resin achieved:

- Approximately 99% recovery yield

- ~97.9% HPLC purity

- Efficient elution using only 0.5 M NaCl, enabling simplified downstream processing

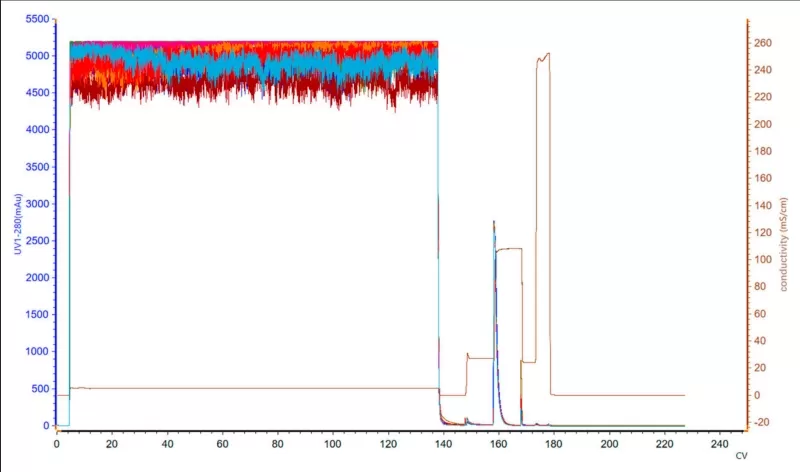

Fig. 4. Overlay of the cycles 1,10, 20, 30, 40, 50, 60, 70, and 80 chromatograms obtained by passing 130 CV skimmed milk containing 0.3 mg/L bLF through a 1.6 · 20 cm (CV = 40 mL) column packed with SP Seplife 6AG XL 200 at 2 minutes contact time. Impurities were eluted with 0.24 M NaCl, bLF was eluted with 1 M NaCl. bLF, bovine lactoferrin.

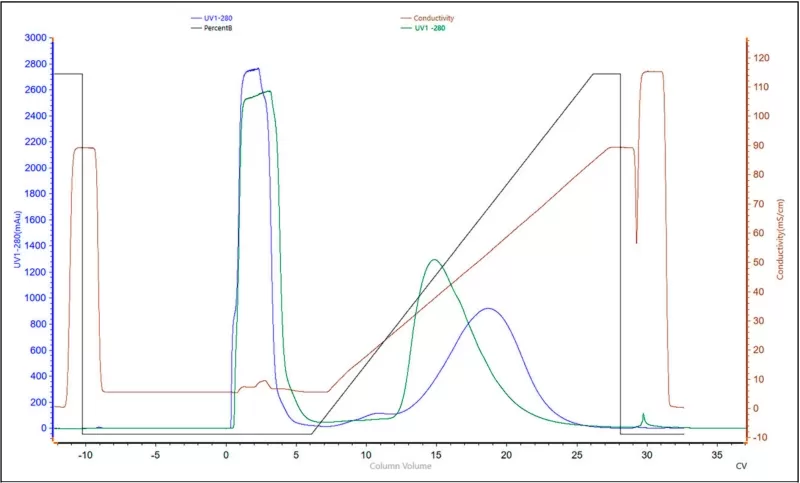

Fig. 5. Elution profile of rbLF using a gradient elution from 50 mM to 1 M NaCl. The feed loaded to the column was filtered, undiluted fermentation broth. SP Seplife 6AG XL 200 (blue) and Seplife SP5504C (green). The experiment was done in a 1.6 · 10 cm (20 mL) column at 5 minutes retention time.

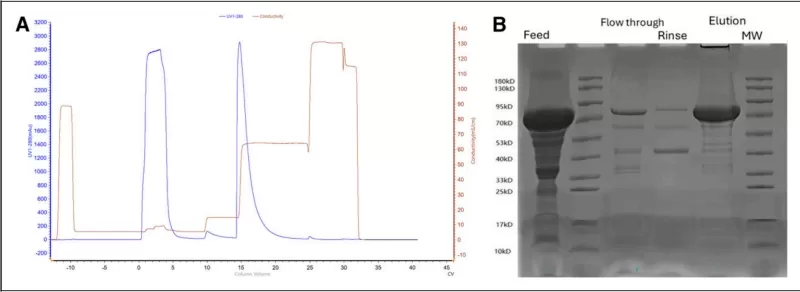

Fig. 6. Step elution profile for rbLF using SP Seplife 6AG XL 200 with a 96.4% recovery using 0.7 M NaCl elution solution (A) and the corresponding SDS-PAGE of the different fractions (B).

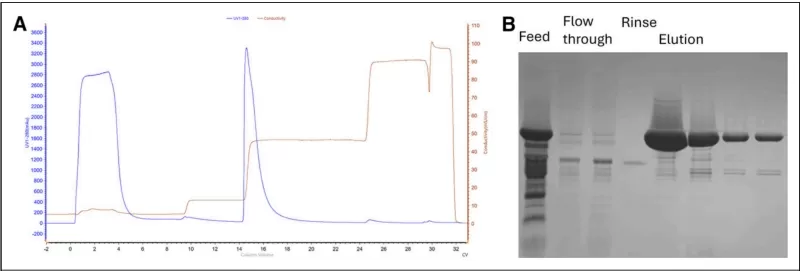

Fig. 7. Step elution profile for rbLF using Seplife LXPM SP5504C with a 99% recovery using 0.5 M NaCl elution solution (A) and the corresponding SDS-PAGE of the different fractions (B).

Process optimization showed that performance was strongly influenced by operating conditions such as feed pH and flow rate. At an optimized pH of around 5.5, the resin maintained high purity and yield, even at elevated linear velocities, supporting high-throughput production requirements.

Selecting the Right Resin for Different Lactoferrin Sources

This case study highlights an important practical conclusion: lactoferrin purification performance depends strongly on feed origin, and resin selection should be application-driven.

- For dairy-derived lactoferrin, where concentrations are lower and feed composition is more complex, SP Seplife® 6AG XL 200 provides superior recovery and stable performance.

- For fermentation-derived lactoferrin, where productivity and capacity are critical, Seplife® LXPM SP 5504C offers high yield, excellent purity, and efficient operation.

Conclusion

By combining tailored resin design with a deep understanding of application requirements, Sunresin’s Seplife® cation exchange chromatography resins provide reliable, scalable solutions for lactoferrin purification across diverse production routes. Whether processing dairy streams or high-titer fermentation broth, Sunresin enables manufacturers to achieve high purity, strong recovery, and consistent operational performance—supporting the growing global market for lactoferrin-based products.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

19

2025 11

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit