Advancing Ergothioneine Production with Adsorption and Separation Technology

To address the high impurity and salt levels in ergothioneine (EGT) fermentation processes, Sunresin has introduced the LX-1880 uniform particle ion exchange resin. Developed to support innovations made in synthetic biology, advanced chromatography systems, and stringent quality control, this specialized resin is designed for desalination, decolorization, and impurity removal. The LX-1880 resin achieves over 95% removal rates for inorganic and organic salts, even in high-salt conditions, enabling efficient and clean separation.

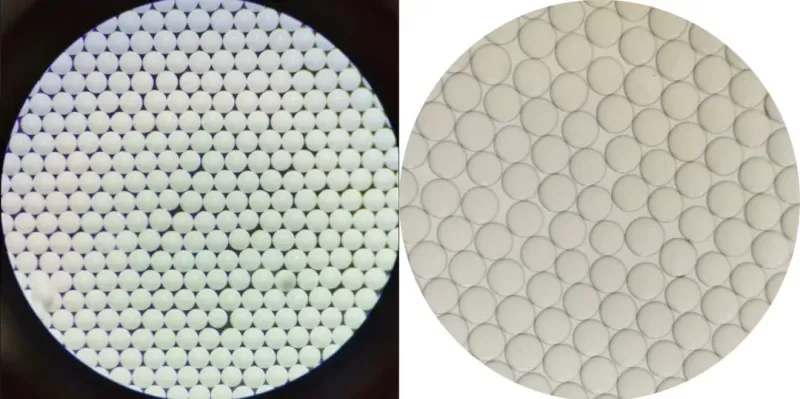

Image: Uniform particle resin under a microscope

The uniform particle size of LX-1880 reduces bed layer pressure drop, allowing for increased processing throughput and significantly lower resin breakage compared to conventional resins. This innovation leads to more effective impurity and salt removal, which increases downstream process yield, optimizes production efficiency, and ultimately reduces overall costs.

Desalination and Purification of EGT Fermentation Liquid with SSMB Technology

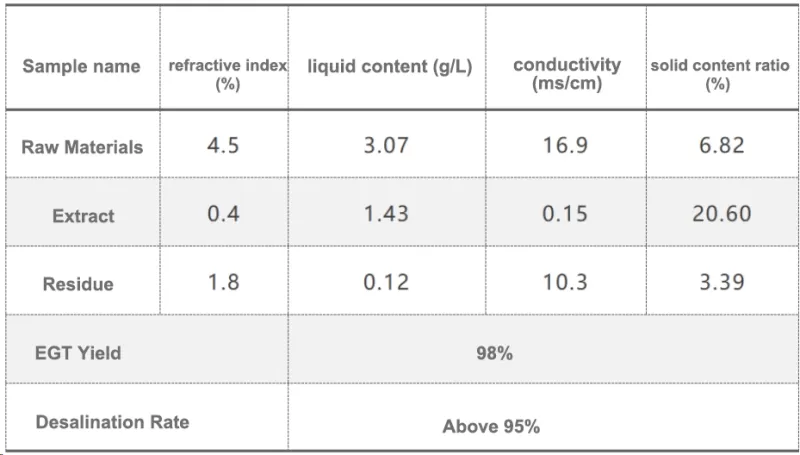

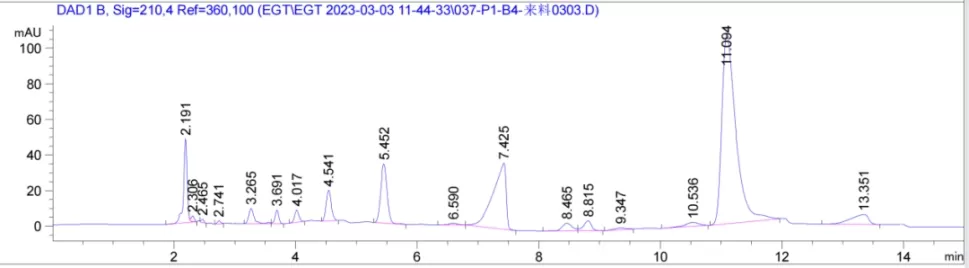

Experimental Results: Leveraging Sunresin’s chromatography expertise, the following results were achieved for EGT fermentation liquids:

- EGT concentration in the extracted solution increased significantly after separation.

- Pigments and unknown impurities were concentrated in the residual phase.

- Desalination efficiency reached over 95%, and EGT recovery rates exceeded 98%.

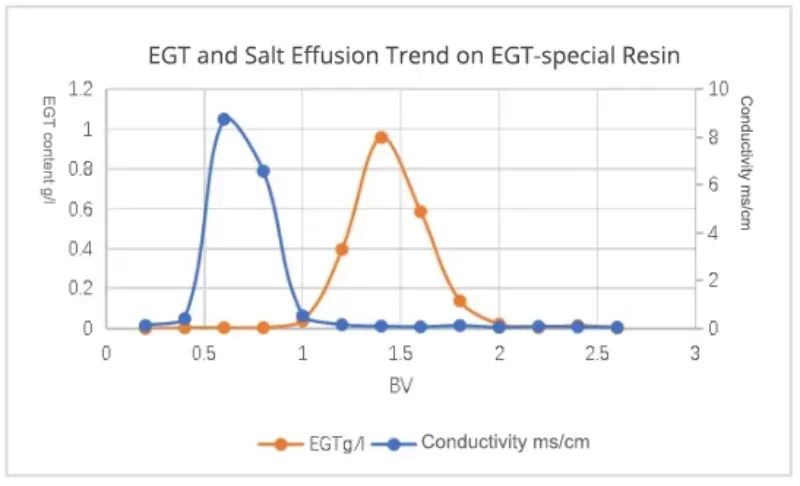

Single-Column Separation Experiment: In EGT feed solutions, pigments separated faster than EGT, showing a distinct separation trend between solid impurities and EGT on the chosen chromatographic resin.

Multi-Column Separation Experiment: In a multi-column desalination experiment for EGT, the feed solution initially contained around 3.07 g/L of EGT with a conductivity of approximately 16.9 ms/cm. Using Sunresin’s SSMB (Simulated Sequential Moving Bed ) chromatography system with the specialized EGT resin, the process achieved over 98% EGT recovery and a desalination rate exceeding 95%.

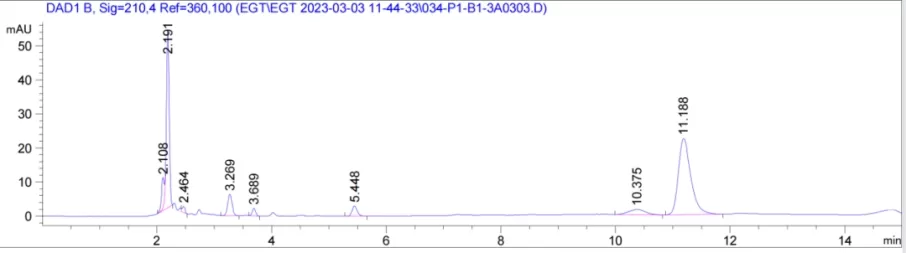

Image: Extraction liquid phase diagram

Images: Liquid phase diagrams of extraction and fermentation solutions

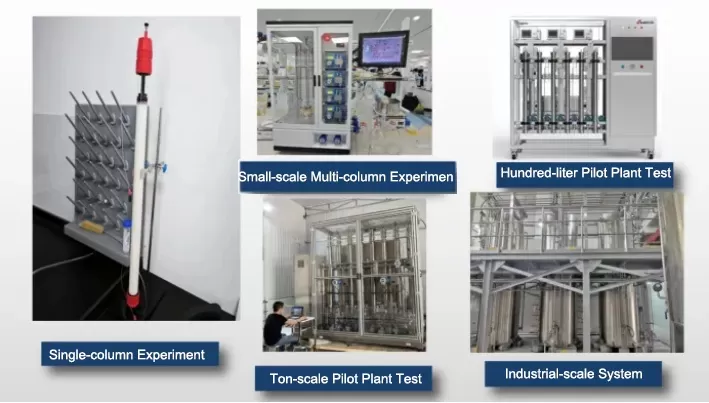

Application of Continuous Chromatography in Ergothioneine Production

Sunresin’s SSMB chromatography system, backed by a dedicated team, supports the entire journey from lab-scale trials to large-scale production, with over 20 chromatography systems available for small, pilot, and industrial applications. This complete development process helps ensure seamless scale-up, enabling commercialization for Sunresin’s partners.

Ergothioneine: A Potent Antioxidant with Expanding Applications

Ergothioneine (EGT) is a naturally occurring amino acid known for its powerful antioxidant properties, high stability, and non-toxicity, increasingly recognized for its positive effects on health. Initially extracted from mushrooms and ergot, its natural sources offered low yields, making purification costly - reaching up to $1 million per kilogram. Later, Barnet introduced a chemical synthesis route, reducing EGT’s market price to approximately ¥7000/g, though still costly. However, advances in synthetic biology have significantly reduced production costs, making EGT more accessible.

Today, three main biosynthetic methods for EGT production exist:

1.Natural Fermentation: Using natural microorganisms, like edible mushrooms, that synthesize EGT through liquid fermentation.

2.Biotransformation: Synthesizing EGT by expressing ergothioneine synthase in plasmids with substrates such as L-His, L-Cys, and L-Met.

3.Engineered Fermentation: Utilizing engineered EGT-producing strains. Synthetic biology techniques are applied to optimize key enzymes within ergothioneine synthesis pathways and precursor amino acid metabolism. Combined with metabolic and fermentation engineering, this approach allows for efficient, high-yield EGT production.

Driving Innovation in Separation and Purification

At Sunresin, we are pioneering advancements in resin and chromatography systems to optimize ergothioneine production, reducing costs and raising product quality. Discover how Sunresin’s innovative separation technology can elevate your production capabilities. Contact us today to learn how our tailored solutions can drive success in your processes. Sunresin – Driving Innovation in Separation and Purification Technology.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

01

2025 07

Sunresin Bioprocess Materials Achieve DMF Registration, Supporting Global Biopharma Compliance

Sunresin has obtained 10 Drug Master File (DMF) registrations for its chromatography resins used in antibody, vaccine, and gene therapy production. With 9 more products under review, Sunresin provides robust regulatory support for global pharmaceutical customers and accelerates IND/NDA filing efficiency with FDA and EMA compliance.

05

2025 06

Sunresin Secures Australian Patent for Lithium Adsorbent Innovation

Sunresin New Materials Co., Ltd. is pleased to announce that its invention titled “A Lithium Adsorbent and Its Preparation Method” has been officially granted a patent in Australia.

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit