A Modular Cartridge Filter Design Improving Reliability and Maintainability of Large-Scale Adsorption Columns

Background: Structural Reliability Challenges in Large-Flow Adsorption Columns

In large-scale adsorption systems handling high gas flow rates, internal filtration components play a critical role in protecting adsorption media and ensuring stable long-term operation. Cartridge filters installed inside adsorption columns are required to withstand continuous gas flow, corrosive environments, and mechanical stress during operation, transportation, and maintenance.

In conventional designs, inner and outer cartridge filters are typically manufactured as one-piece welded structures and permanently fixed to the lower head or internal flat cover of the column. While structurally simple, this configuration often leads to practical challenges during long-term operation, especially when maintenance or replacement is required.

Operational Pain Points in Conventional Filter Cartridge Structures

In real industrial applications, traditional integrated cartridge filter designs commonly face the following limitations:

1. Limited resistance to corrosion and mechanical damage

Process gases may contain corrosive components, and even minor damage during installation, welding, or transportation can significantly reduce filter service life.

2. High maintenance and replacement costs

Once a cartridge is damaged, replacement often requires cutting or dismantling major structural components, resulting in long downtime and high labor costs.

3. Poor replaceability and flexibility

One-piece structures do not allow partial replacement, forcing operators to replace entire assemblies even when damage is localized.

These challenges increase operating costs and reduce equipment availability, particularly in large adsorption columns designed for continuous operation.

A Modular and Service-Friendly Cartridge Filter Solution

To address these issues, Sunresin developed a modular cartridge filter structure specifically designed to improve maintainability, reliability, and economic performance in large-flow adsorption columns.

Modular design enables efficient replacement and reduced maintenance cost

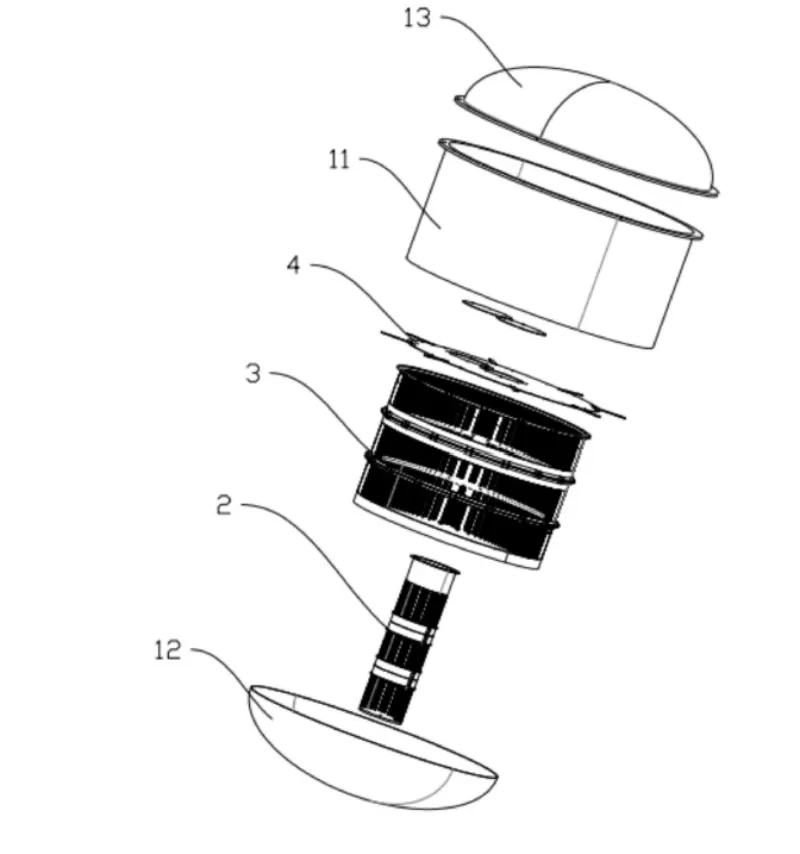

Both inner and outer cartridge filters are divided into multiple independent filter modules. Each module can be installed or replaced individually, allowing maintenance to focus only on affected sections rather than the entire filter assembly. This significantly reduces downtime, labor intensity, and replacement cost.

Optimized head structure improves strength and accessibility

The lower head is permanently welded to the column shell to ensure overall mechanical strength and structural stability. The upper head adopts a detachable connection, enabling easier loading of adsorption media as well as convenient access for inspection and maintenance.

This separation of structural and maintenance functions improves both equipment robustness and service efficiency.

Dedicated inspection access supports faster maintenance

Inspection openings connected directly to the cartridge filters are integrated into the top cover and sealed with flanged covers during operation. These access points allow quick internal inspection and maintenance without dismantling major components, helping shorten shutdown periods.

Limiting components enhance stability in tall column configurations

Multiple limiting components are installed around the outer circumference of the cover plate to prevent cartridge movement caused by external forces or vibration. This design ensures stable positioning of both inner and outer cartridges, even in high-column or high-flow operating conditions.

Delivering Long-Term Value Through Structural Optimization

By combining modular design with optimized structural support, this cartridge filter solution significantly extends equipment service life, reduces maintenance frequency, and lowers total cost of ownership. The design also provides greater flexibility for future upgrades and adaptation to different operating scenarios.

This case demonstrates how thoughtful equipment engineering—focused on maintainability and real operating conditions—can deliver tangible economic and operational benefits for adsorption systems.

As part of its integrated approach spanning materials, process design, equipment, and system solutions, Sunresin continues to advance adsorption equipment technologies that support reliable, efficient, and sustainable industrial operation.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

19

2025 11

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit