Sunresin Chelating Resin for Nickel Removal: Advanced Solution for Electroplating Wastewater Treatment

Nickel-containing wastewater is a major byproduct of Printed Circuit Board (PCB) manufacturing, originating from both electroplating and electroless plating processes. With tightening environmental regulations and growing demand for resource recovery, efficient treatment of nickel-laden wastewater—especially in high-salinity, low-concentration systems—has become an urgent industry challenge.

Sunresin offers a specialized chelating resin designed for selective nickel and cobalt removal, empowering customers to meet strict discharge standards and achieve valuable metal recovery.

Understanding Nickel Wastewater: Sources and Treatment Challenges

Nickel-bearing wastewater in electroplating industries primarily comes from post-plating rinsing, filtrate disposal, spilled plating solutions, and floor wash-downs. This wastewater often includes both:

- Free Ni²⁺ ions – typically treated with chemical precipitation, ion exchange, or membrane filtration;

- Complexed Ni ions – which require breaking the chelating bonds (often via oxidation) before further removal.

Electroplating wastewater is complex, variable in composition, and can include multiple metal ions and fluctuating pH levels. Efficient treatment requires not just basic removal, but selective separation and low residual concentrations, especially under high-salinity conditions.

Ion Exchange: Preferred Method for Deep Nickel Removal

Ion exchange is widely recognized for its excellent effluent quality, metal recovery potential, and suitability for large-volume, low-concentration streams. The principle is simple: resin functional groups exchange ions with those in the water. Once saturated, the resin is regenerated using an acid such as HCl or H₂SO₄, enabling multiple use cycles.

However, conventional cation or generic chelating resins often suffer from poor selectivity, limited capacity, and mechanical degradation in high-salinity systems, reducing their suitability for complex industrial scenarios.

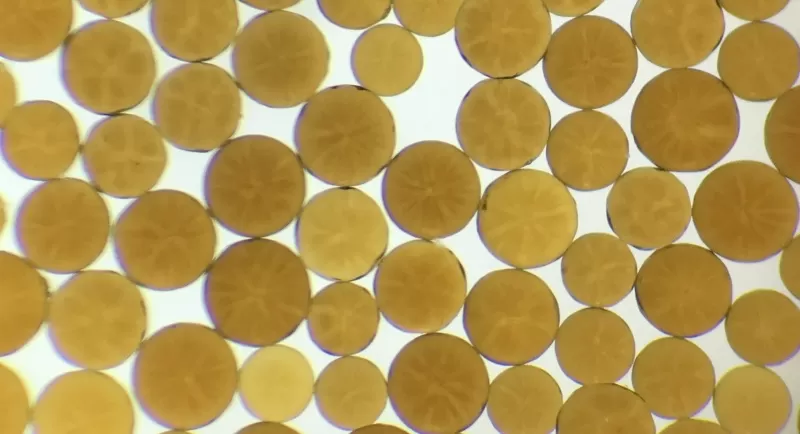

Sunresin’s Chelating Resin: Tailored for High-Performance Nickel & Cobalt Removal

Sunresin’s proprietary nickel-selective chelating resin is engineered to overcome the limitations of traditional media. Its advantages include:

- Exceptional Selectivity

The resin’s functional groups exhibit high affinity for Ni²⁺ and Co²⁺, while remaining largely unaffected by Na⁺, Ca²⁺, Mg²⁺, Mn²⁺ and other background ions. This enables targeted removal of trace nickel and cobalt even in brine-rich environments.

- High Exchange Capacity

The working exchange capacity exceeds that of typical chelating resins by over 10%, delivering both higher metal uptake and higher regeneration concentrations, facilitating downstream recovery.

- Strong Mechanical Properties

With a crushing strength ≥95%, the resin is resistant to degradation in high-salt, continuous-flow operations, ensuring long service life and system stability.

- Efficient Regeneration

Nickel and cobalt can be fully desorbed using acids (e.g., >5% HCl or >10% H₂SO₄), allowing for low-cost, high-efficiency reuse of the resin in cyclic operations.

- Uniform Particle Size Distribution

The resin meets international standards for particle size consistency, minimizing pressure drop and promoting stable operation across various column configurations.

Wide Applications Across Industries

Sunresin’s chelating resin is currently used in diverse sectors, including:

- PCB and surface finishing industries

- Electroless plating and wastewater treatment

- Metallurgical processing

- Ternary battery recycling

- Spent catalyst recovery

It is suitable for both inorganic nickel and complexed nickel species, especially under weak acid or neutral conditions. Combined with upstream oxidation or chemical precipitation processes, it serves as an ideal polishing step for trace-level nickel removal (≤0.1 mg/L) in final discharge.

Partner in Green Manufacturing and Resource Recovery

Backed by over 20 years of R&D in adsorption and separation, Sunresin delivers not only high-performance materials, but also complete system solutions. Our customized nickel removal technologies are already implemented across environmental remediation, electronics, energy storage, and metal refining sectors in China and abroad.

We continue to innovate in separation science to support a cleaner and more sustainable industry.

Contact us to learn how our chelating resins can help solve your nickel and cobalt separation challenges.

Free Quote

Resources

Adsorbent Resin

Bio-Pharmaceutical & Life Science

Enzyme Carriers

Hydrometallurgy & Mining

Chelating Resin

Chemical Industry

Chromatographic Media

Wastewater Treatment&Reuse

Food & Beverage Industries

Ion Exchange Resin

Civil & Industry Water Treatment

Equipments And Projects

Plant Extraction

Catalyst Resin

Solid Phase Peptide Synthesis

Product

Application

Contact Us

Sunresin Park,No.135, jinye Road, Xi’an Hi-tech Industrial Development Zone, Shaanxi-710076, China

seplite@sunresin.com

seplite_europe@sunresin.com

+86-29-89182091

Our Product List

Latest News

01

2025 07

Sunresin Bioprocess Materials Achieve DMF Registration, Supporting Global Biopharma Compliance

Sunresin has obtained 10 Drug Master File (DMF) registrations for its chromatography resins used in antibody, vaccine, and gene therapy production. With 9 more products under review, Sunresin provides robust regulatory support for global pharmaceutical customers and accelerates IND/NDA filing efficiency with FDA and EMA compliance.

05

2025 06

Sunresin Secures Australian Patent for Lithium Adsorbent Innovation

Sunresin New Materials Co., Ltd. is pleased to announce that its invention titled “A Lithium Adsorbent and Its Preparation Method” has been officially granted a patent in Australia.

11

2025 04

SZSE Visits Sunresin – An ETF Constituent Company in the CSI 500 Index

On the morning of March 28, the Shenzhen Stock Exchange (SZSE), along with representatives from Harvest Fund and over 30 other participants, visited Sunresin— a constituent company of the CSI 500 Index — for a special research and engagement activity.

Leave a Message

Please send any questions you want to know, we will reply to you immediately.

Choose File

Submit